content is empty!

| SKU: | |

|---|---|

| Availability: | |

| Quantity: | |

FSM

EDWIN

0.4-0.75KW;0.55-1HP

12.6-18m3/h

12-18m

intelligent

Description :

The 0.75kW sewage submersible pump with intelligent model is a reliable and efficient solution for pumping sewage, rainwater, mud water, and high-viscosity fluids in a variety of applications. Its submersible design, intelligent features, and robust specifications make it a valuable tool for civil engineering projects, building sites, and other environments where effective drainage and fluid transfer are essential.The pump is equipped with intelligent features that enhance its performance, efficiency, and control capabilities. This intelligent model allows for advanced monitoring, automation, and customization of pump operations.

Operating conditions :

- Max water depth : The pump can operate at a maximum water depth of 10 meters, making it suitable for pumping water from deep underground sources or confined spaces.

- Water temperature : The pump can handle water temperatures up to +40°C, allowing it to operate effectively in a wide range of environmental conditions.

Specifications :

- pH range : The pump is suitable for use in water with a pH range of 6.5 to 8.5, ensuring compatibility with various water sources and conditions.

- Insulation class : The pump is rated with insulation class F, indicating its ability to withstand high temperatures and provide enhanced safety during operation.

- Protection class : The pump has a protection class of IP68, ensuring it is fully sealed against dust and can withstand continuous immersion in water up to a depth of 10 meters without water ingress.

Options on request

Intelligent model

Float switch

Other voltages or frequency

Materials Table

| NO. | Name | Material |

| 1 | Hose coupling | Cast iron |

| 2 | Handle | Rubber&steel |

| 3 | Upper cover | Aluminum die casting |

| 4 | Up-Bearing house | Cast iron |

| 5 | Seal house | Cast iron |

| 6 | Motor body | Aluminum die casting |

| 7 | Pump body | Cast iron |

| 8 | Impeller | Ductile iron |

| 9 | Agitator | Stainless steel |

| 10 | Sand guard | NBR |

| 11 | Oil riser | LDPE |

| 12 | Seat assembly | PU |

| 13 | Stator | |

| 14 | Rotor | Shaft : AISI420SS |

| 15 | Bearing | Ball bearing |

| 16 | Bearing | Ball bearing |

| 17 | Capacitor | |

| 18 | Motor protector | |

| 19 | Mechanical seal | Ceramic-Sic/Carbon-Ceramic |

| 20 | Gasket | NBR |

| 21 | Gasket | NBR |

| 22 | Gasket | NBR |

| 23 | Shaft sleeve | AISI420SS |

| 24 | Cable | H07RN-F |

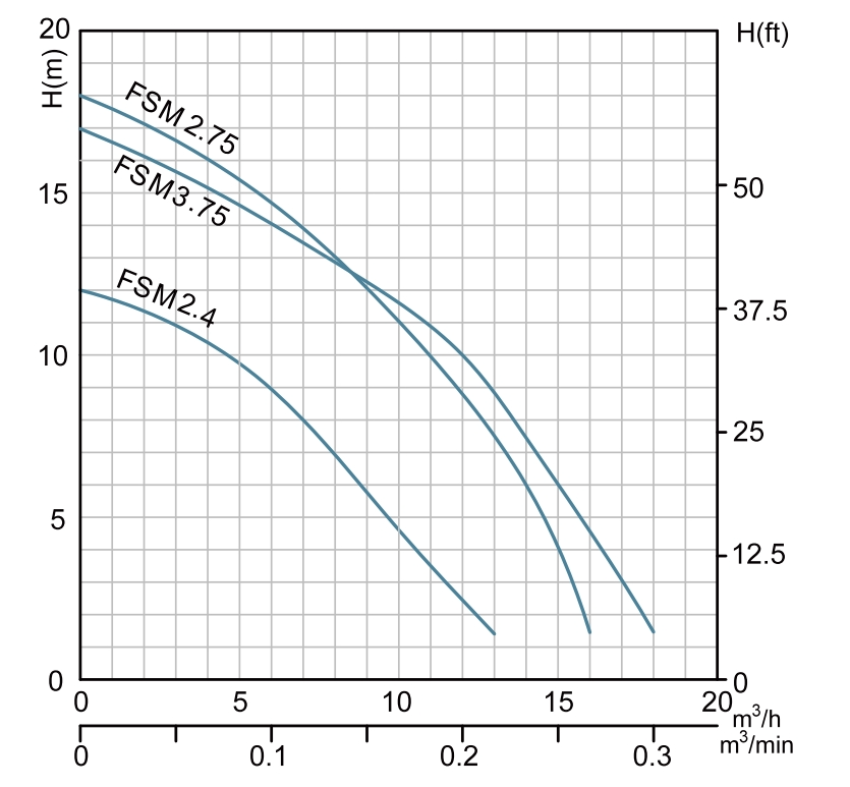

Performance Curves :

Performance Data :

Description :

The 0.75kW sewage submersible pump with intelligent model is a reliable and efficient solution for pumping sewage, rainwater, mud water, and high-viscosity fluids in a variety of applications. Its submersible design, intelligent features, and robust specifications make it a valuable tool for civil engineering projects, building sites, and other environments where effective drainage and fluid transfer are essential.The pump is equipped with intelligent features that enhance its performance, efficiency, and control capabilities. This intelligent model allows for advanced monitoring, automation, and customization of pump operations.

Operating conditions :

- Max water depth : The pump can operate at a maximum water depth of 10 meters, making it suitable for pumping water from deep underground sources or confined spaces.

- Water temperature : The pump can handle water temperatures up to +40°C, allowing it to operate effectively in a wide range of environmental conditions.

Specifications :

- pH range : The pump is suitable for use in water with a pH range of 6.5 to 8.5, ensuring compatibility with various water sources and conditions.

- Insulation class : The pump is rated with insulation class F, indicating its ability to withstand high temperatures and provide enhanced safety during operation.

- Protection class : The pump has a protection class of IP68, ensuring it is fully sealed against dust and can withstand continuous immersion in water up to a depth of 10 meters without water ingress.

Options on request

Intelligent model

Float switch

Other voltages or frequency

Materials Table

| NO. | Name | Material |

| 1 | Hose coupling | Cast iron |

| 2 | Handle | Rubber&steel |

| 3 | Upper cover | Aluminum die casting |

| 4 | Up-Bearing house | Cast iron |

| 5 | Seal house | Cast iron |

| 6 | Motor body | Aluminum die casting |

| 7 | Pump body | Cast iron |

| 8 | Impeller | Ductile iron |

| 9 | Agitator | Stainless steel |

| 10 | Sand guard | NBR |

| 11 | Oil riser | LDPE |

| 12 | Seat assembly | PU |

| 13 | Stator | |

| 14 | Rotor | Shaft : AISI420SS |

| 15 | Bearing | Ball bearing |

| 16 | Bearing | Ball bearing |

| 17 | Capacitor | |

| 18 | Motor protector | |

| 19 | Mechanical seal | Ceramic-Sic/Carbon-Ceramic |

| 20 | Gasket | NBR |

| 21 | Gasket | NBR |

| 22 | Gasket | NBR |

| 23 | Shaft sleeve | AISI420SS |

| 24 | Cable | H07RN-F |

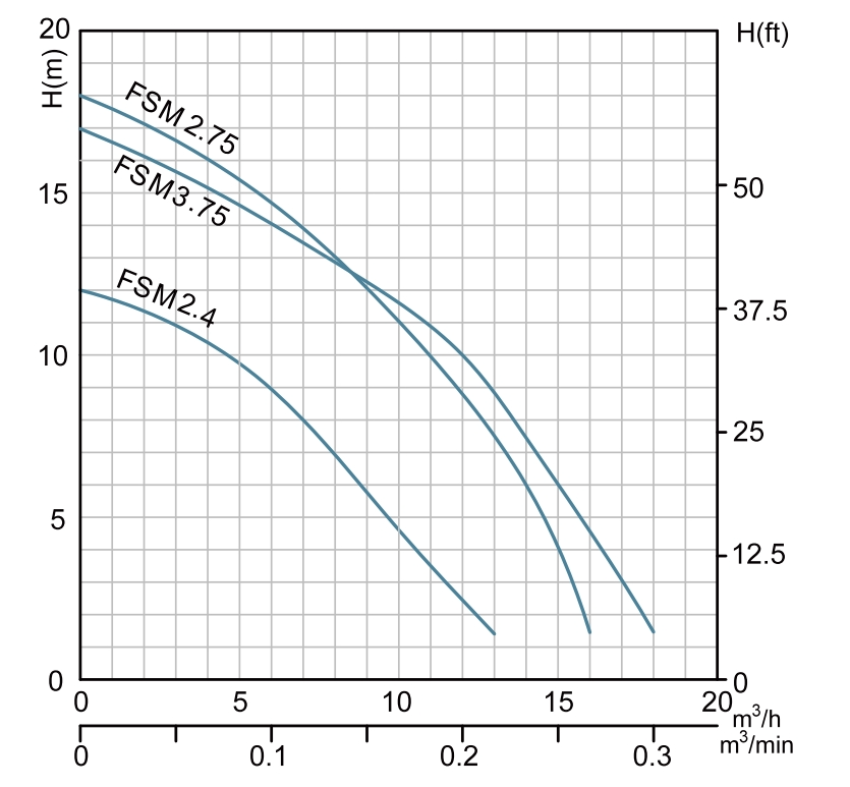

Performance Curves :

Performance Data :